I use a stainless dump pump from harbor freight. You talk about blasting the sanitizer. I think it was only about $50

Announcement

Collapse

No announcement yet.

4 head bottle filler for $275

Collapse

X

-

El_mocoso, can you post a picture of the back of your filler? I'm interested in seeing how you did the manifold to the four fillers. Also, what material did you use for the stand?

Originally posted by el_mocoso View PostJohn,

I really admired your set-up and design and went ahead and built one similar to yours and Nat's.

I am also going to use Morebeer rinser and purger. In your demonstration video, it looked like you were turning off and on a pump for a sani loop. Can you point me in the right direction for a pump that would fit the needs for this operation?

Again, thanks for the great ideas and designs. I'm attaching our version which we just field tested for the first time yesterday to bottle our GABF beers. We adjust for different size bottles with the spacers under the grates that the bottles sit on. It worked real nice.

Cheers!

[ATTACH]18523[/ATTACH]

Comment

-

Comment

-

1/2" line

Hi folks, wondering what product you are using for your 1/2" line from the bright. Is it cynic beer line or the more rigid stuff?

Are you then stepping down to 6 feet of 1/4" beer line?

I've built one of these and am trying to get it working now for our new brewery.

Thanks

Comment

-

I ran 1/2" beer line to the first T, then 5/16" until the last section where I used 1/4". I don't think you have to restrict/balance the flow like you would a regular beer faucet because it is a pressurized bottle so it shouldn't foam up like it would pouring a beer into a glass.

Comment

-

Find a solution?

Johnny,

Did you ever find a solution to this? I know you can get replacement spouts for gravity fillers but not sure how to do an auto-shutoff for a counter-pressure filler. We built a version of this filler last year and are working on a new version with a bunch of upgrades this year.

Originally posted by johnnymax View PostAnybody know where I can get, or make bottle filler valves that will shut off automatically?

If I can just load the bottle, purge and hit fill and the valve shut when it fills, I will be able to have more filling heads.

It my not be possible to make, but I wonder if I can buy a replacement filling valve from an existing machine that would work?

Any Ideas?

Comment

-

No, I never was able to find or design an auto shut off for the fillers. So we manually shut them off when full still :-(Originally posted by vinesrushes View PostJohnny,

Did you ever find a solution to this? I know you can get replacement spouts for gravity fillers but not sure how to do an auto-shutoff for a counter-pressure filler. We built a version of this filler last year and are working on a new version with a bunch of upgrades this year.John McKissack

Texas Big Beer Brewery

Newton County, Texas

Comment

-

Modifications to design

One of our goals for modifying this unit is to make it easier to sanitize and eliminate fittings and connections where possible. And, in looking at the common commercial 4 spout sparkling filling machine, that machine is using a balance tank with a site glass, a supply line and possibly a bleedoff valve? Here's the link to that machine from GW Kent: http://www.gwkent.com/4-spout-sparkl...g-machine.html

I'm planning to use a TriClamp manifold like this (http://www.glaciertanks.com/TriClamp...riClamp_1.html) with a sight glass and end camp on the end (acting as the balance tank) and 1/4" barbed x TC fittings for each individual filler with a short 1/4" liquid line of maybe 8" length or so. The line running from the Brite tank will probably be 3/8" or 1/2" to a barbed fitting X TC connecting to the other end of the manifold.

By using the tri-clover fittings and limiting other permanent fittings, this setup simplifies sanitation. The "balance tank" I'm guessing gives a more consistent flow to the filling spouts - I'm sure there's a reason it's used in the commercial design.

Any thoughts on this setup, considerations I'm missing, things that just won't work with this design?

Comment

-

I built one of these and ran our version for a while until I started to really worry about the ball valves collecting gunk and being impossible to clean. It's great as a short term option but I'd either swap out the ball valves every 6 months or so or move on to a more sanitary option.

Comment

-

You, know we are still using the original prototype I built 3 years ago with the original valves. We run boiling hot sanitizer through it for at least 30 minutes before and after we bottle and we seal it up with sanitizer in it between bottling.John McKissack

Texas Big Beer Brewery

Newton County, Texas

Comment

-

We built a growler filling station out of these which is working pretty well. We find that after a few weeks the valves are leaking co2, they don't seem to be off fully in any position.

Are there alternative sources for these valves? Or better versions of these valves that anyone knows of?

Comment

-

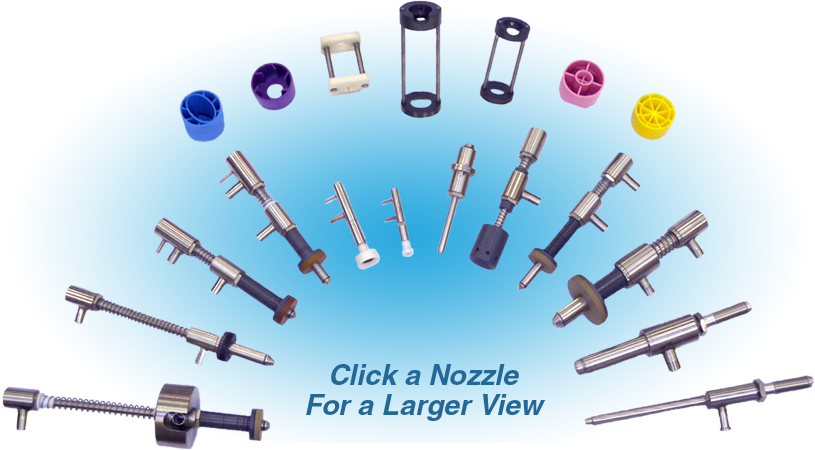

Nozzle supplier

I came across this company in my searches for a nozzle - producing a variety of different nozzle styles and selling those in addition to manufacturing full filling units - but not really for the wine/cider/beer market. Someone with more of an understanding of the technical side of counter-pressure can help figure out if there's a nozzle here that's a good fit or could be custom produced to fit the purpose.Originally posted by johnnymax View PostNo, I never was able to find or design an auto shut off for the fillers. So we manually shut them off when full still :-(

Packing Dynamics

Comment

Comment