My glycol unit doesn't seem to be able to cold crash my tanks fast enough. 10bbl and it takes about 2 days to go from 70F -> 36F. This is with one other BT maintaining 36F temp. I can not get any my tanks to go below 35F. I'm thinking my glycol ratio is off.

What tool do I need to test my glycol?

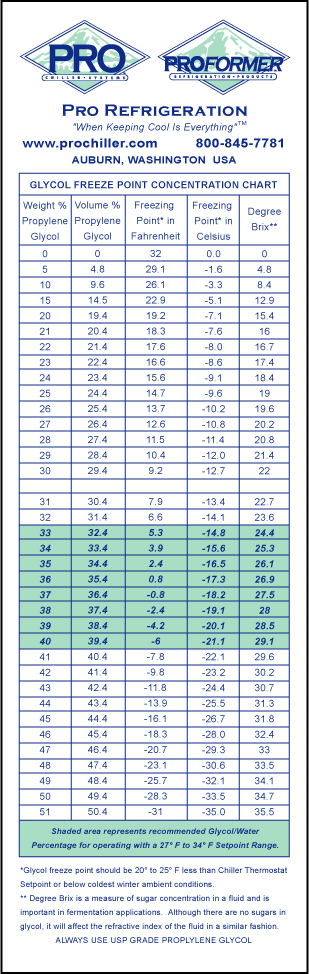

How do I know what the proper ratio of glycol to water should be?

What tool do I need to test my glycol?

How do I know what the proper ratio of glycol to water should be?

Comment