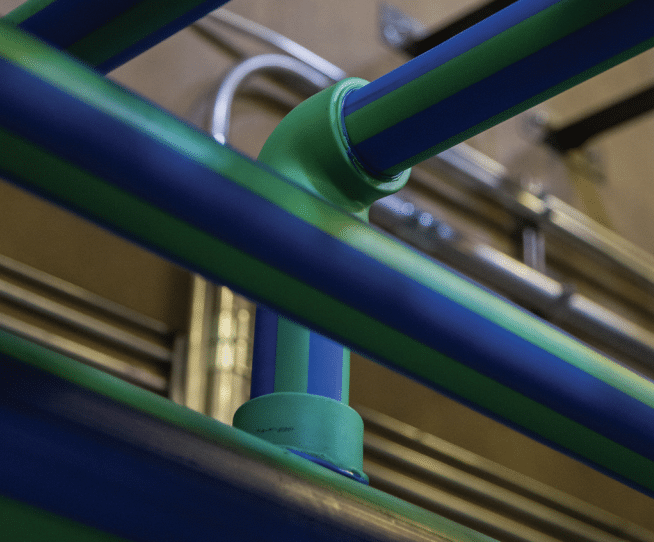

So I am getting ready to replace the mish-mash of plug-in chillers I have in the brewery with an actual dedicated outdoor chiller and plumbed glycol loop. (Yeah, I know welcome to the real world right?) I have a question about mounting the actual piping to the wall. One of the runs will travel along the side of my walk-in cooler and I am unsure if I should mount the piping to the wall of the cooler or rig it down from the ceiling. The cooler walls are very stable, even if you slam the door. The occasional bump from the pallet jack does cause a little vibration though. Would anyone consider this an issue? I am afraid over time the occasional vibration may cause a joint to leak but don't know if I am over-analyzing things. I know suspending from the ceiling would probably be "safer" but with the height of my ceilings in that area, it will be an expensive PITA to rig it that way.

Just curious if anybody else has done this or is it a big no-no.

Thanks as always...

Just curious if anybody else has done this or is it a big no-no.

Thanks as always...

Comment