Well, it was time for my semi-annual capper maintenance, so I thought I'd get out the old Nikon and document it for you all. This is very photo-heavy, and for some reason, IMG code is turned off for me at this board, so you'll have to click on the links. All the links lead to one of my Flickr accounts, so they are safe.

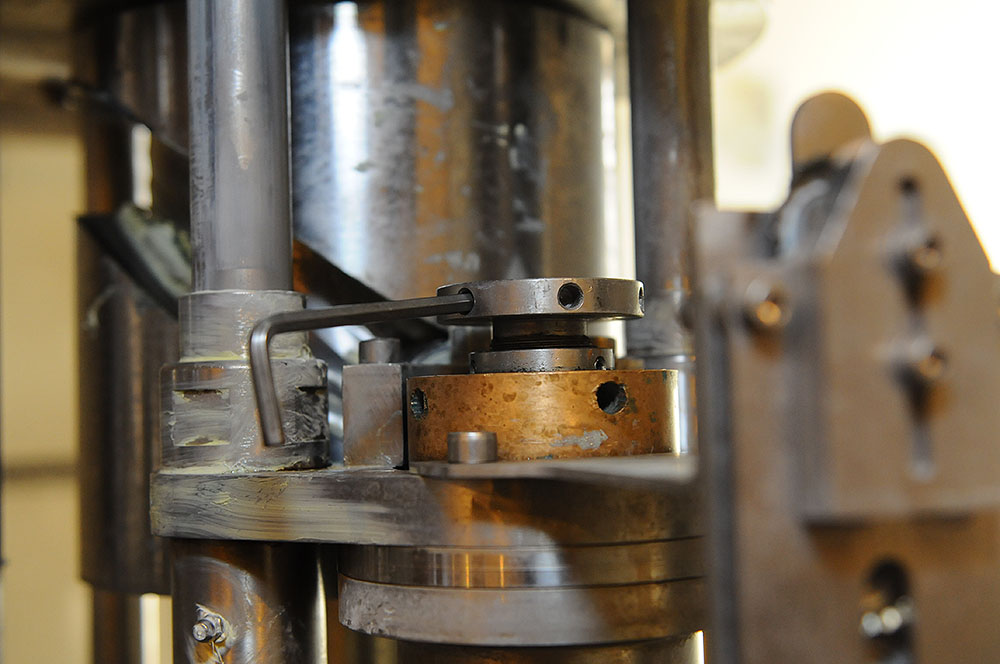

The assembly I'll be working on is the part of the crowner that goes up and down and actually puts the crowns on. The diagram is on pg. 76 of the GAI 3003 Bier manual. Please, ignore the "Adjusting the crown head closure position" instructions on this page--they are wrong! I'll explain the proper procedure when I put the critter back together.

First, tools needed:

A full set of metric Allen wrenches--we'll be using the 2.5, 4, 5, 6, and 8mm. A 3/8" drive X 6mm Allen ratchet wrench will make thing easier, but you can get by with the regular Allen wrench. Ditto the 4mm Allen on a 1/4" drive handle.

14mm deep socket X 3/8" drive.

1 1/2" X 3/8" extension.

3/8" ratchet drive.

8mm combination end wrench.

Not in photo:

2 or 3 3/4" cube steel blocks--you can probably get away with wood or plastic blocks, but if they fail....

6" X 7mm hard steel rod. A 6mm Allen wrench will work, but the 7mm is much better. I ground a piece of 3/8" drill rod down.

OK, let's get wrenchin'!

With the capper at top dead center (highest point in its travel), loosen but do not open the gate that holds the lower caps channel closed. Using the 6mm Allen wrench, remove the bolt that retains the lower caps channel:

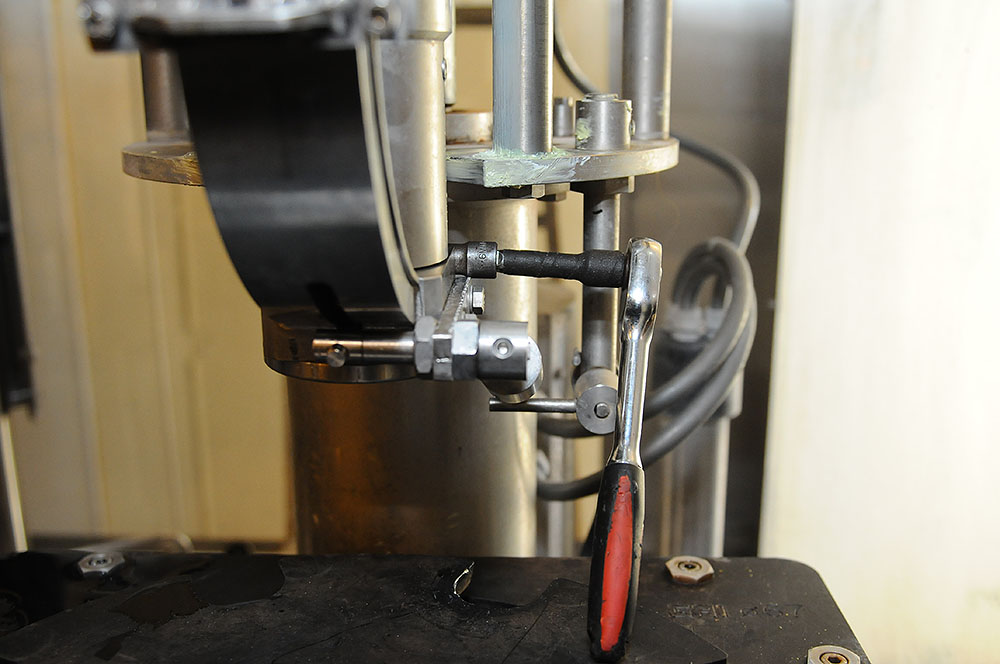

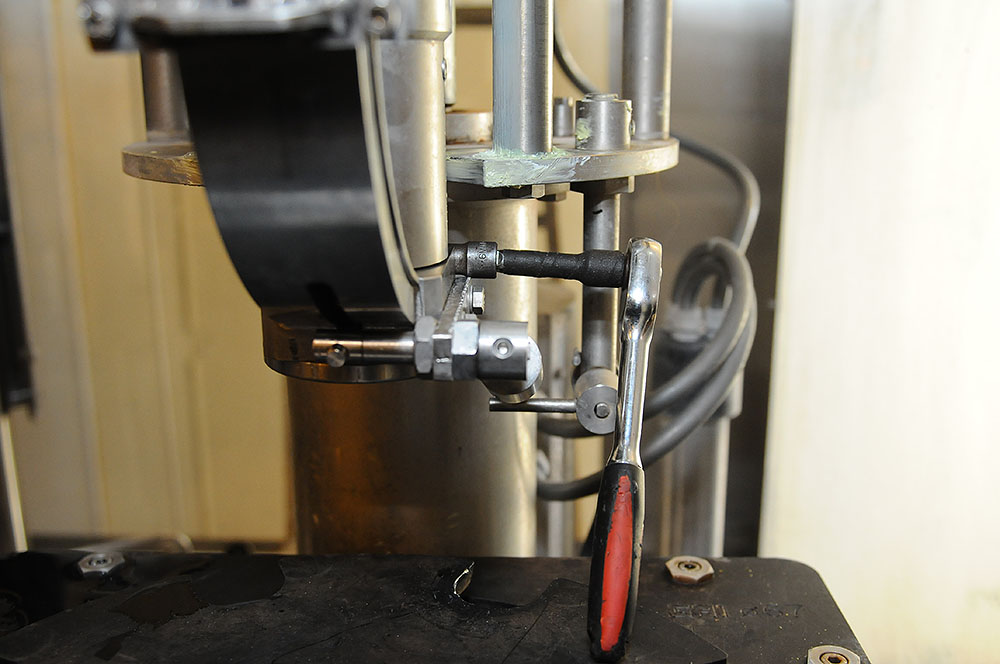

With the 5mm Allen wrench, loosen the retaining screw for the crowner lower unit (on the right hand side of the crowner assembly):

The lower unit should slide right out, if not, you can use a 6mm Allen wrench in the bottom of the caps pusher (D in diagram on pg 76) to wiggle it loose:

Advance the machine until the crowner assy is at bottom dead center--lowest point.

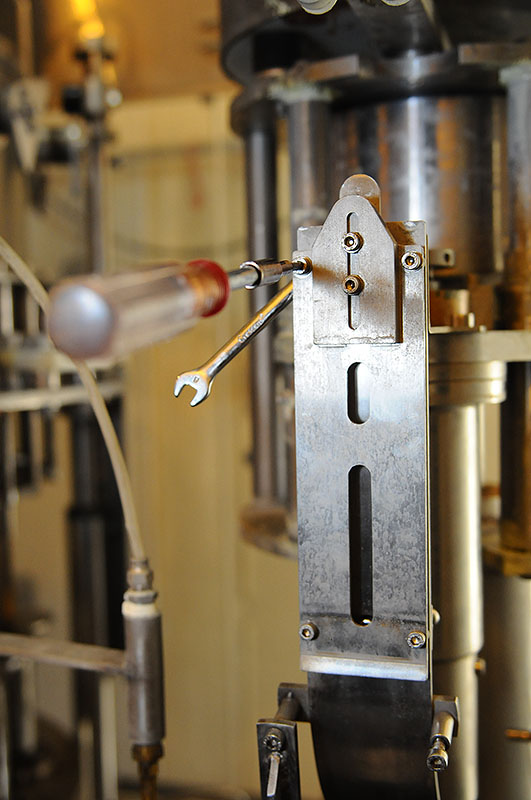

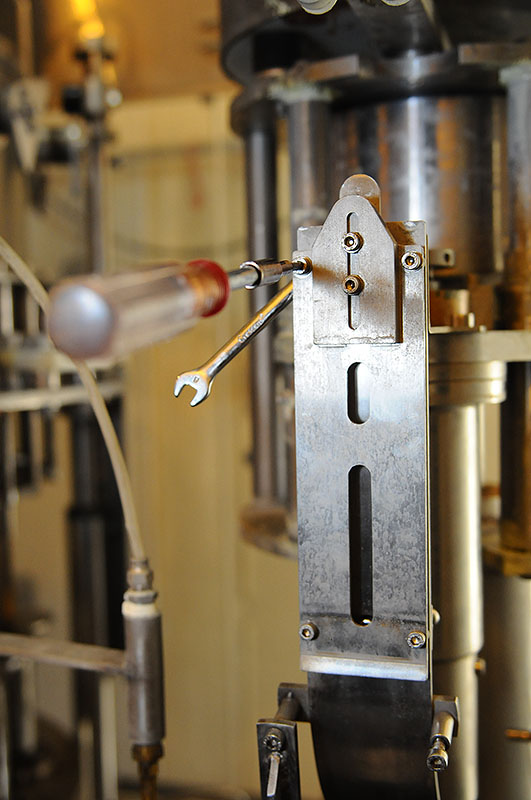

With a 4mm Allen wrench and an 8mm combination wrench, loosen--don't remove--the screws that retain the lower caps sensor bracket:

and slide the sensor and bracket off. Let it dangle out of the way.

With the 14mm deep socket, remove the greasy (it had better be) bolt with the Zerk fitting at the back of the top of the assembly:

With the 6mm Allen wrench, slightly loosen all four bolts at the top of the crowner assy. Remove the front two bolts:

This will free the top support for the caps back plate, but you still need to remove the nuts from the two screw at the top of the caps channel (4mm Allen wrench, 8mm combo) and remove the support piece:

Be careful not to lose any washers or spacers, and screw the nuts back on--finger tight is fine.

Advance the machine until the crowner assy. is about 1/4-1/3 of the way up, and remove the remaining two bolts from the top (oops, forgot to get a picture). You might want a hand to catch and lower the rather heavy assy, but I manage it on my own. Pull the assy. down and out. Remove the drive cam follower assembly from the drive cam and inspect it for cracks/corrosion/wear. If the shaft looks like this:

You're going to be talking to Prospero--and you've put off this maintenance too long.

Take the major parts back to the shop and open a beer!

I'm going to take a break and try to finish this tutorial tomorrow.

The assembly I'll be working on is the part of the crowner that goes up and down and actually puts the crowns on. The diagram is on pg. 76 of the GAI 3003 Bier manual. Please, ignore the "Adjusting the crown head closure position" instructions on this page--they are wrong! I'll explain the proper procedure when I put the critter back together.

First, tools needed:

A full set of metric Allen wrenches--we'll be using the 2.5, 4, 5, 6, and 8mm. A 3/8" drive X 6mm Allen ratchet wrench will make thing easier, but you can get by with the regular Allen wrench. Ditto the 4mm Allen on a 1/4" drive handle.

14mm deep socket X 3/8" drive.

1 1/2" X 3/8" extension.

3/8" ratchet drive.

8mm combination end wrench.

Not in photo:

2 or 3 3/4" cube steel blocks--you can probably get away with wood or plastic blocks, but if they fail....

6" X 7mm hard steel rod. A 6mm Allen wrench will work, but the 7mm is much better. I ground a piece of 3/8" drill rod down.

OK, let's get wrenchin'!

With the capper at top dead center (highest point in its travel), loosen but do not open the gate that holds the lower caps channel closed. Using the 6mm Allen wrench, remove the bolt that retains the lower caps channel:

With the 5mm Allen wrench, loosen the retaining screw for the crowner lower unit (on the right hand side of the crowner assembly):

The lower unit should slide right out, if not, you can use a 6mm Allen wrench in the bottom of the caps pusher (D in diagram on pg 76) to wiggle it loose:

Advance the machine until the crowner assy is at bottom dead center--lowest point.

With a 4mm Allen wrench and an 8mm combination wrench, loosen--don't remove--the screws that retain the lower caps sensor bracket:

and slide the sensor and bracket off. Let it dangle out of the way.

With the 14mm deep socket, remove the greasy (it had better be) bolt with the Zerk fitting at the back of the top of the assembly:

With the 6mm Allen wrench, slightly loosen all four bolts at the top of the crowner assy. Remove the front two bolts:

This will free the top support for the caps back plate, but you still need to remove the nuts from the two screw at the top of the caps channel (4mm Allen wrench, 8mm combo) and remove the support piece:

Be careful not to lose any washers or spacers, and screw the nuts back on--finger tight is fine.

Advance the machine until the crowner assy. is about 1/4-1/3 of the way up, and remove the remaining two bolts from the top (oops, forgot to get a picture). You might want a hand to catch and lower the rather heavy assy, but I manage it on my own. Pull the assy. down and out. Remove the drive cam follower assembly from the drive cam and inspect it for cracks/corrosion/wear. If the shaft looks like this:

You're going to be talking to Prospero--and you've put off this maintenance too long.

Take the major parts back to the shop and open a beer!

I'm going to take a break and try to finish this tutorial tomorrow.

Comment